Metric Mechanic Engine Parts

Please call 573-765-1269 for pricing

M20 Crankshaft Seal Spacer for M50 to S52 Cranks

The Metric Mechanic M20 Crankshaft Seal Spacer enables installation of the M50, M52, S50, S52 Crankshaft. This spacer is specially commissioned by MM and available only from us. The final finish is machine polished, so smooth that it will not damage the front crankshaft seal. It is a standard part in all our M20 3 liter and 3.2 liter engines, fitting the 84mm, 86mm and 89.6mm stroke cranks. Not shown is the specific length bolt and machined washer that are included.

Top and side view of MM 3200 Rally piston for M50, M52, S50, S52 Engines

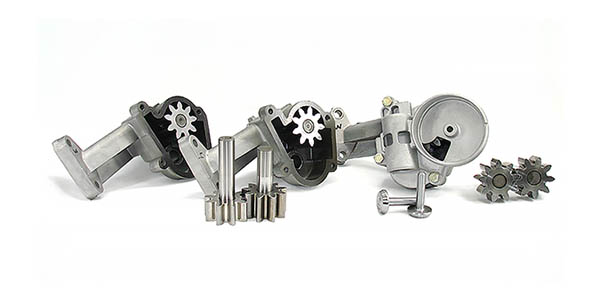

Valve Spring Kit Description: M50-S52-M54 & M42-M44 Metric Mechanic Rally Valve Spring Kit: Shim, Spring Perch, Inner Spring, Outer Spring & Valve Spring Retainer

Metric Mechanic Dual Valve Springs

Solving Valve Train Problems

BMW Valve Train Followers (Rocker Arms & Lifters) have evolved over the years. Early SOHC M10/ M30 and M20 engines used aluminum rocker arms with a “cast in cast” iron foot up to about ’92. First generation DOHC S14/ S38 & S88 M POWER engines used a “shim over” mechanical lifter bucket. In ’91 BMW came out with the M50 and started the use of the hydraulic lifter bucket. This has been used in the M50, M50tu, M52, M52tu, S50, S52, and M54. Also, it is used in the V8′s of this period, the M60 to the S62. When running a hotter or a stock cam in any of these engines, our valve springs will prevent valve bounce while actually increasing the reliability of the valve train. This is done by running (at maximum lift) less than stock cam nose pressure, to prevent wear and tear on the valve train. Increasing seat pressure keeps the exhaust valve from bouncing off the seat during closing and hitting the piston. Early on as company, we figured out how to prevent cam/ lifter wear problems and it’s all done with correct valve spring pressures.

Story #1 THE TELL ALL RACING VALVE SPRINGS FROM HELL

In the summer of 1987 one of our employees named Mot (not his real name) was circle track racing an M10 engine in a mini sprint (looks like a midget). The year before Mot won the points championship and was leading in points about halfway into the ’87 season. A weekend was coming that he didn’t have a race. Mot had been running stock factory rocker arms and stock single wound M10 valve spring shimmed up.030″. The engine was being run up in the range of 7900 to 8100rpms. Mot was worried that the springs might be fatiguing. So, he bought a set of hot looking race valve springs. The springs had an outer and inner coil (wound in the same direction) with a flat wire damper (wound in the opposite direction) tightly sandwiched between the other two coils. The springs looked like they came from a Chevy. Compared to the single wound stock spring he had been running, these babies looked hot! With the new race valve springs in his engine, Mot felt this was just the insurance he needed to win another points championship. The next race, he breaks 4 rocker arms. So he thinks the rocker arms, after a season and a half, must be fatigued out and need replacing. Mot pulls off the head and notices that the exhaust valves have been lightly hitting the pistons. He leak checks the head by pouring solvent down the ports. The head appeared to be good. Next he installs 8 new Febi rocker arms. The following race, his crew chief was wrapping (revving) up his engine in the pit area, when suddenly something let go under the valve cover. When the valve cover was removed, all 8 of the new Febi rocker arms were broken. Before the “Hot” race valve springs, his engine had never broken a rocker arm using the stock valve spring shimmed up .030″. Because the valve spring was the only thing that he changed, he concluded that the valve springs were breaking the rocker arms. So, Mot went back to the stock springs and replaced the rocker arms. This stopped the rocker arms from breaking, but the engine started loosing oil pressure about half way through a race and knocking out rod bearings. This happened 4 or 5 times. Each time he had to rebuild the engine and replace the bearings. Mot asked me if I would go to to his next race and be his crew chief for the night. I said yes. Before the start of the race, I checked out the tune of the engine. While I was checking the valve lash, I noticed a lot of oil seeping from the cam bearing journals, while Mot was cranking over the engine. That night his engine lost oil pressure once it got warmed up and blew up. This time, when the engine came apart, I reminded him of how much oil I saw coming from the cam journals. We measured the cam bearing clearance, it was worn out to .008″ (it should be at .001″ to .0015″). This is where he was losing his oil pressure. Again, none of this was going on before the race valve springs were installed. The only conclusion, that made sense, was that the spring pressure was so high, at full cam lift, that it wore out the cam bearing areas of the head. If the nose pressure was so high, then how could the exhaust valves be hitting the pistons? I concluded that the seat pressure was too low and the exhaust valve was bouncing off the seat hitting the piston near top dead center, as it tried to close during overlap. When I measured the seat and nose pressure of “THE TELL ALL RACE SPRING FROM HELL” and the stock M10 valve spring with .030″ shimming, here was the result:

- Race spring from hell (inner and outer spring wound in the same direction with a flat dampening coil sandwiched in between and rubbing the other two coils).

- Seat pressure 62#

- Open (nose)pressure 240# @ 11mm lift

- Nose to seat pressure ratio 3.87:1

- BMW Stock M10 spring (single wound spring with .030″ shimming).

- Seat pressure 68#

- Open (nose) pressure 188# @ 11mm lift

- Nose to seat pressure ratio 2.76:1

Because there was no cam change, the engine was red lined at about the same 8000rpm with no missed shifts and the race spring was the only thing changed, one could conclude the following:

- The additional 52# (240#-188#= 52#) of pressure at full cam lift caused the rocker arms to break and the cylinder head cam bearing area to wear out.

- Lowering the seat pressure 6# (68#-62#= 6#) caused the exhaust valves to lightly hit the pistons.

If we look at the two springs above, the stock spring was working at 68# of seat pressure at 8000rpm. Lets look at how many pounds of seat pressure per 1000 rpm is needed in a M10 engine. Using the stock spring with a .030″ shim as an example, the answer comes out to 8.5#/ 1000 rpm. The Race spring from hell, the exhaust valves were hitting the pistons and floating at 7.75#/ 1000 rpm. Over the years, I have measured at what rpm valve float has occurred in various BMW rocker arm engines (M10, M30,& M20). Here is the rule of thumb I’ve come up with on seat pressure:

MM rule of thumb on SEAT PRESSURE8# to 9# of seat pressure is needed per 1000 rpm – using the BMW factory rocker arm, stock valve, dual valve spring, and steel retainer

As for nose pressure, it needs to be kept as low as possible. As the nose (the top half of the cam lobe) gets bigger, the valve will stay open longer, more air will come into the engine, and it will rev higher. This results in more horsepower! Because the valve is staying open longer as the engine rev’s higher, the dwell time the rocker arm stays up on the nose doesn’t really change that much from a stock cam to a full race cam. So, a race cam doesn’t really need any more nose pressure to control the valve at high rpm.

After the incident, with the “Race Spring From Hell”, I spent three months researching nearly 1500 valve springs, trying to find the right valve spring for us. The ideal spring would need to generate rather low nose pressure to keep from tearing up the valve train. My goal was to generate less than stock nose pressure. A way to express the difference between the seat and nose pressure can be done by dividing the nose pressure by the seat pressure. I refer to this as, THE NOSE TO SEAT PRESSURE RATIO. Using stock spring pressures of 188#/68#, we came up with a ratio of 2.76:1. The Race spring from Hell, has a nose to seat pressure ratio of 3.87:1. The ideal spring would need a nose to seat pressure ratio as low as possible. In the end, the ideal combination inner and outer (dual) spring I found, generates a seat to nose pressure ratio of about 2.00:1, with the following spring pressures:

Metric Mechanic Dual Valve Spring we currently use.

- Seat pressure – 77# @ 1.460″ installed height

- Open (nose) pressure 153# @ 11mm lift

- Nose to seat pressure ratio 1.99:1

- Spring travel to coil bind – 15.85mm

Keep the nose pressure as low as possible. A seat to nose pressure ratio of 2.00:1 is excellent, 2.25:1 to 2.50:1 is good, and not over 2.75:1.

Story #2 Testing Spring Theory and Design at the Track

A few years later, we did a lot of asphalt circle track racing. We built a half dozen M10 race engines for local Kansas City area BMW racers. Over several seasons we raced 2002s, a 320i, and a 318i. We generally finished 1st or 2nd. We raced at two tracks, a 1/2 mile and a 5/8 mile track. At the smaller track we would exit off a corner at about 7700 rpm and at 8300 to 8400 rpm at the end of the straight away. At the larger 5/8 mile track we would hit 9100 rpm at the end of the straight away. On restarts, for just a burst, we sometimes hit 10,000 rpm. We were running a piston to valve clearance of .050″ on the exhaust side. This is tight! The outer valve spring we raced with back then, is still the same spring we use today on our dual wound springs. At the time, we were running a Mercedes Benz inner spring (that years later was replaced with a lighter spring) that gave us a total spring pressure of:

Metric Mechanic race dual valve spring back in the early ’90s’

- Seat pressure – 78# @ installed height

- Nose pressure – 175# @ 11,3mm cam lift

- Seat to nose pressure ratio 2.24:1

Using our Metric Mechanic dual springs (with these pressures) and stock rocker arms; we never broke rocker arms, had valves hit pistons, experienced valve float, broke valve springs, or wore out cam bearings. Honestly, the only valve train failure I can remember, is a camshaft that broke in half just behind second cam journal. I believe the cam broke, due to metal fatigue, caused by very high RPM vibration over too much running time.

After the Valve Spring From Hell incident, we’ve always run less than stock nose pressure on the Metric Mechanic performance engine we build. This assures that reliability and longevity of the valve train will be greater than a stock engine, while at the same time, freeing up some horsepower even though we are using hotter cams with more lift. No one wants to buy a fast engine that breaks or wears out prematurely.

MM Duel valve springs offer these advantages over single wound, bee hive, or cone springs.

- The valve spring pressure is shared between two springs instead of just one.

- With our Dual Valve Spring, the outer spring takes 72% of the spring load (110# at 11mm lift) and the inner spring 28% (43# at 11mm lift). A single spring, would bear all the load pressure (153# in this case) and be more prone to failure in a high rpm situation.

- If a spring breaks, a Dual valve springs offer a better margin of safety. In about the last 10 years, we’ve seen an increasing number of broken outer valve springs on S14 and S38 engine cores sent in for rebuilding. These are stock dual spring. The outer spring will usually break about a third of the way up from the bottom and the valve will get bent but we’ve never seen a valve head broken off from hitting the piston, due to a broken stock spring. The inner spring offers enough back up spring pressure to prevent this from happening.

Story #3 Fatal Low Valve Seat Pressures on S14 and S38

Now, we have seen dual wound Shrick valve springs, used in S14′s, break off valve heads and bend valves due to valves bouncing off their seats, caused by low seat pressures (42#). In the two instances that we’ve seen this, the heads and pistons were obliterated from flying shrapnel. By comparison, a low revving ETA/M20 engine that floats it’s valves at 5700rpm, has a seat pressure of 48#. A stock S14/S38 spring runs 78# of seat pressure. We run 90# of seat pressure with our dual springs and 25# less nose pressure (at 11mm lift) than stock. This prevents valve bounce and reduces power loses while increasing timing chain and guide rail life. The outer spring we use, is the same spring we’ve used since 1987 and have never had a spring failure with it. We reuse the inner spring on S14 and S38 engines because, they don’t fail, it holds down costs, and we know their safety margin.

Spring harmonics are better controlled with a dual wound valve spring because the outer and inner springs are wound in opposite directions to each other. So the harmonic wave given off by the two springs opposes and cancels each other out. Some people believe that the outer and inner spring should rub against each other to reduce spring harmonics. This practice is mostly used with the American V8 crowd. Besides building BMW engines, in the past I’ve rebuilt engines in other foreign cars and motorcycles, I’ve never seen this practice. The rest of the world, that I’m aware of, runs a gap between the inner and outer spring. As a spring compresses it generates heat. I feel that rubbing the two coils together will only cause the springs to run hotter. Heat is the enemy of spring life. With our MM Dual wound spring the coils don’t touch.

Story #4 Valve Keepers Pulling Through Stock S50/ S52 Valve Retainers

Over the years, we have observed E36/M3 heads with valve keepers pulling though valve retainers. It’s more common on the stock ’95/S50 than the later S52 head. Also we have seen failed retainers on heads where shims (usually .030″) were used under stock valve springs to increase spring pressure for use with a stock or hotter cams. Also, coil bind will occur if one tries to use M3 cams with factory cone springs from the E36/325i or 328i. When we started seeing these problems, we conducted load tests on stock E36/M3 retainers to to see how many pounds of pressure it took to pull the keepers though the retainer’s 7 degree tapered hole.

- The ’95 stock S50 retainer pulls though at 165#

- The ’96 and later retainer failed at 185#

The two retainers look identical but the later retainer is slightly heat treated. This prompted us to come up with a much stronger MM Chrome Moly retainer that can take 300# before pulling through.

The stock cone spring that is used on the E36/M3 is also used on the M44 engine.

The coil wire diameter can be .138″ or .141″ and has the following spring pressures:

- Seat pressure – 61# at installed height

- Nose pressure – 148# at 11mm lift

- Seat to nose pressure ratio 2.43

In the past we have used “bee hive” springs in MM Sport/ Rally engines, but by mid summer of 2014, we decided to only use dual springs in all our engines. The MM Dual valve spring, we use with hydraulic lifter bucket engines M50, M50tu, M52, M52tu, S50, S52, M54, M42, M44, M60, and S62 have the following spring pressures:

- Seat pressure – 68# at installed height

- Nose pressure – 142# at 11mm lift

- Seat to nose pressure ratio 2.09

In the MM Rally Engines we build for the E36 crowd, we shim up the oil pump’s pressure relief valve by 8# and with this spring setup, it is good to about 7700 rpm. The lower spring nose pressure, combined with higher oil pressure, keeps the lifter from collapsing at high rpms. Drivers that track or race a BMW with hydraulic lifter buckets, will sometimes hear valve clatter when exiting the track. What they’re hearing is excessive valve lash caused from too much oil leaving the lifter bucket at high rpms and causing the lifter to temporarily collapse. A more dangerous problem is famous “MONEY SHIFT”. This happens when the lifter bucket leaves the cam lobe and pumps up at high rpms from a missed shift (the driver trying to up-shift but accidentally down shifts causing a serious over rev). When the lifter pumps up, the valves can hit the pistons, causing then to bend or break. Our MM Dual Springs with 10% more seat pressure help minimize this problem.

In summary

Metric Mechanic uses the same outer spring that we discovered over 25 years ago from racing. An outer spring which in our experience has never broken or collapsed. They have a great margin of safety in case of an over-rev or a spring failure. Another reason we’ve stayed with this spring is that we can maintain a seat to nose pressure ratio of about 2.00:1 or less. This really adds to the reliability of the valve train and prevents valve bounce. We use seat pressures of about 65# to 78#, depending on maximum RPM and valve train weight and nose pressures in the range of 145# to 170#, varying by cam lift. The Inner Springs we use vary by head application.

Metric Mechanic

Jim C. Rowe